)

Konecranes retrofits Auto-TOS reporting on other crane brands for ports leader SAGT

Konecranes Port Solutions is changing the container handling playing field by giving container terminal operators the ability to retrofit powerful intelligence to their existing container cranes that would not otherwise be available.

The crane technology retrofits are available throughout Australia, New Zealand and the Asia-Pacific region, as well as globally, and they can be applied to any brand of container crane.

In a recently completed retrofit project, Konecranes Port Services worked with South Asia Gateway Terminals (SAGT) in Colombo, Sri Lanka over the past several years on a retrofit project involving 28 Doosan and 9 ZPMC Rubber Tired Gantry (RTG) cranes in its container yard equipment fleet.

Konecranes Port Services completed an upgraded installation of the Auto-TOS (Terminal Operating System) reporting smart feature on the cranes. The company has already installed more than 35 such systems on non-Konecranes cranes at the terminal, and more than 1000 Auto-TOS retrofits across the globe.

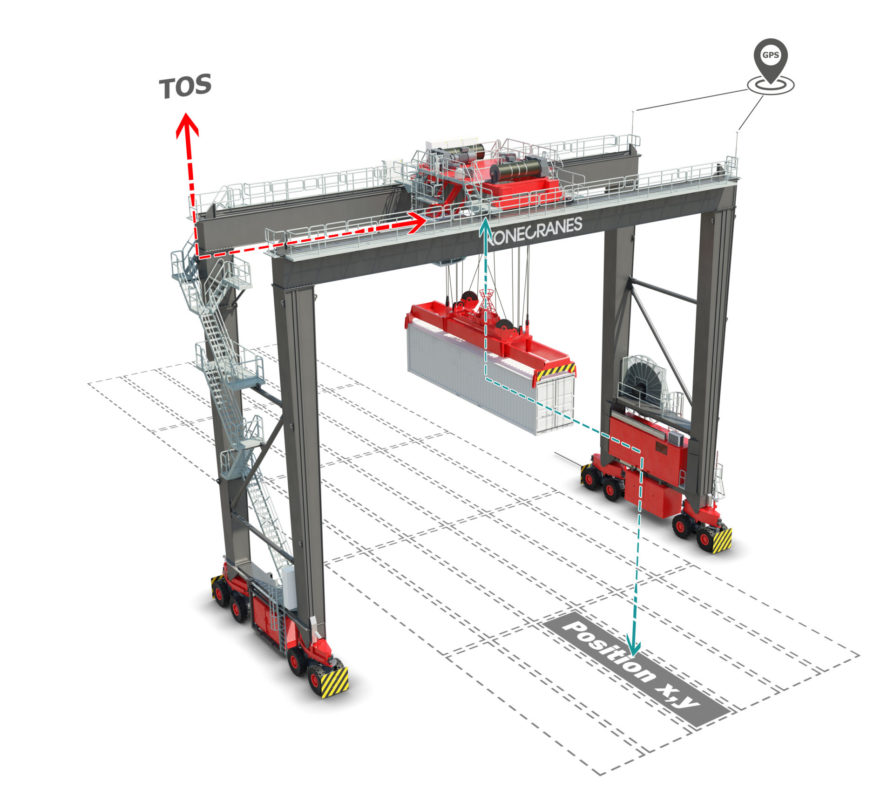

The Konecranes Auto-TOS smart feature allows the crane to accurately report its position to the TOS after every container move. The TOS therefore receives live, accurate data on the position of every container, making it possible for the terminal operator to maintain a container inventory that is 100% accurate.

Auto-TOS can be installed on any brand of container crane, and interfaces with any make of TOS. SAGT’s Auto-TOS reporting retrofit project involved the installation of hardware comprising 37 Konecranes Auto-Positioning reporting systems (one per crane), the Konecranes TOS interface server, two base stations, and four spare systems. It also involved the installation of Konecranes’ proprietary Auto-TOS positioning software. This software works through a DGPS (Differential Global Positioning System) that interfaces directly with the terminal’s TOS.

Chinthaka Abeynaike, IT general manager at South Asia Gateway Terminals, said of the project, “Data is increasingly becoming a key differentiator for our business. By adding this Konecranes technology to our entire RTG fleet we have dramatically improved our live-feed visibility over the yard.”

Cindy Shi, Konecranes marketing manager, Port Services Global, says that this type of retrofit project is part of Konecranes’ path to port automation, where container terminals improve productivity and safety in manageable steps.

“From smart features up to full automation, the path can include supervised operation and remote operation to smoothly introduce the power of automation. The path to port automation applies to all container handling equipment brands. Full automation can be the final goal, but it doesn’t have to be. Flexibility is the key,” she said.