)

Quad pawl range extends safety

Nobles partners with William Hackett Lifting Products to offer quality hoisting, introducing patented Quad Pawl technology into the Australian marketplace.

Patented Quad Pawl technology

Providing operators with increased levels of safety and better performance is paramount to Nobles’ business model, William Hackett’s vision and objectives are the same making them the perfect partner.

Chain hoists are a common choice for lifting and materials handling operations. With the addition of Quad Pawl Technology the William Hackett hoisting range has enhanced the capability of the hoists making them safer.

The William Hackett C4 QP chain hoist range covers a broad range of capacities for all sorts of jobs, large and small. William Hackett C4 QP hoists are available with a working load limit that ranges from 500kg to 50t and across the board these meet and exceed Australian Standard AS1418.2-1997.

Resilience to failure

William Hackett Lifting Products (WHLP) continually challenge itself to innovate, design and manufacture lifting products that are safer and reduce project timelines.

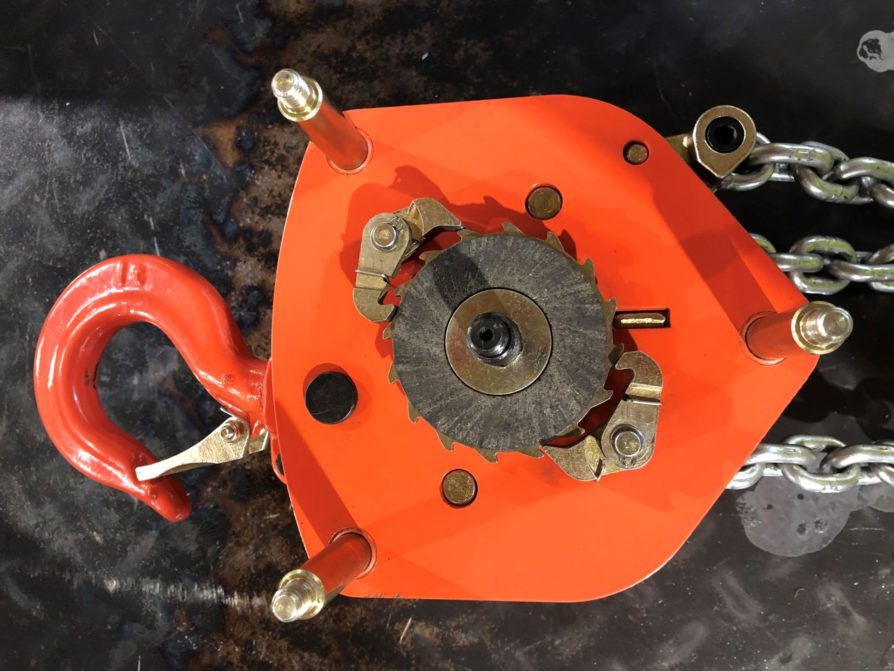

Today, typical chain hoists share similar design features, and the ratchet and pawl is one of the critical systems they hold in common. The characteristic ‘click-click’ noise of the pawls during hoisting is one of those instantly recognisable industrial sounds that tells you a chain block is being used.

The ratchet and pawl in-effect forces the braking mechanism to work by preventing the load from back-driving the gearbox. If the pawls fail the load falls.

In the real old days hoists only had one pawl – and the consequence of failure of this small part with its little spring was serious. It’s little wonder then that nearly any manual chain hoist you encounter nowadays is now fitted with twin pawls.

Little wonder too that as a service item, replacement pawls and springs are a common requirement upon a detailed inspection.

Although mechanical failures in modern hoists are rare, years of experience accumulated within William Hackett Lifting Products identified a fundamental mechanical design change that would eliminate one potential mode of failure whilst increasing product lifespan.

To this end William Hackett has designed, patented, and manufactured its ‘Quad Pawl’ (QP). This technology was originally incorporated in the subsea SS-L5 Lever Hoist and was the first in the world to provide four pawl mechanical engagement. This advanced technology is now also available within the William Hackett range of L5 lever hoists and C4 chain hoists – contact Nobles for further details.

How does it work?

The William Hackett Quad Pawl design isn’t simply a case of whacking in yet more pawls. On each pawl post, there are now two pawls. One of these still looks similar to the traditional version, the second is a partner pawl that has its arm facing the other direction. This forms two sets of two pawls, making four in total. The ratchet ring and pawl are designed together so that as one pawl disengages, its partner engages and the shoulders of these at the pawl post self act upon each other. A helper spring is retained but is no longer critical like the springs were in older style hoists.

Better for the user

Simply making the ratchet and pawl function more reliable isn’t the only benefit of the William Hackett Quad Pawl design – the hoist steps between each bite of the pawls are also smaller. This brings benefits across a great many everyday lifting scenarios where the load must be raised or lowered to a specific position – for our industrial customers that’s practically every flange, every shaft, every gear, every pipe, every gearbox, every motor and more that are hoisted with a manual chain block. Putting a more precise chain hoist in front of your personnel makes them safer, makes jobs run smoother, and further avoids risk of damage to valuable equipment as it is inevitably coaxed into place.

The WH C4 QP have been tested and certified for fleeting or cross hauling applications up to 45deg from the vertical without lowering the rated capability. They use a unique hand chain joiner which is used as a quick and secure method of joining the hand chain without the need to cut, bend, open and close a link of existing hand chain. The rated operational temperature ranges from – 20oC to +120oC.