)

Monitor up to 126 loadcells with Insight software

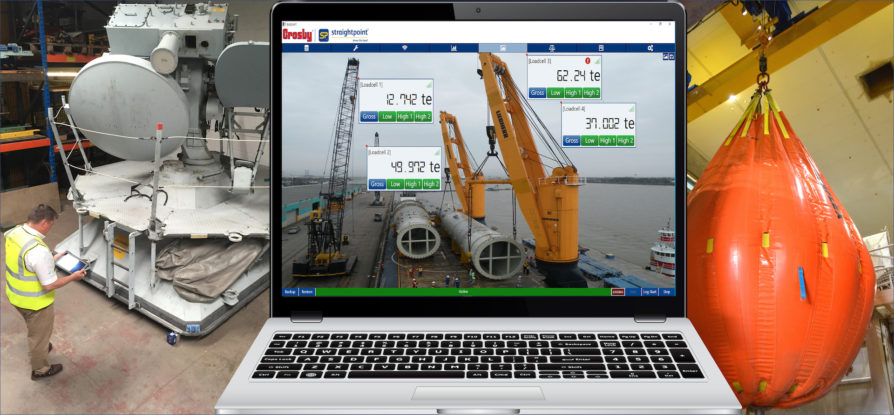

Multifaceted Insight software from Crosby/Straightpoint is designed to monitor up to 126 load cells from up to 700m (2300ft) away, before and during a lift.

The Insight system is a revolutionary centre of gravity tool, presented as an all-round load monitoring product offering state-of-the-art technology in four main areas: multi-channel display and data logging; load visualisation; proof load testing; and centre of gravity. Included is an SW-D USB wireless dongle; the product can be used with a laptop, tablet or other device using Windows.

Using the multi-channel display and data logging mode, users can view and log load data from connected individual and multiple load cells, live on screen and directly into a .csv file for later analysis at speeds of up to 200Hz. The visualisation mode is designed for more complicated lifts and allows import of a photo of the lift in addition to drag and drop load cell displays. In other words, it makes the screen look like the lift. Proof load testing capability allows real-time graphing of load tests and auto-generates test certificates. Finally, INSIGHT can be used to weigh and calculate the centre of gravity of large items and structures.

David Mullard, business development manager at Crosby/Straightpoint, says, “Each of Insight’s main features represents cutting-edge load monitoring technology in their own right, but what really distinguishes the system is its ability to perform all of those tasks—from multi-channel data logging to centre of gravity – with one single software purchase and wireless dongle. Compared to alternative solutions on the market, Insight offers superior functionality and user-friendliness. What we’re delivering is therefore unprecedented.”

Mullard explained that Insight is used to scan for wireless load cells within a 700m (2300ft) area, which allows an entire site to be monitored, or a select number of load monitoring products on a planned critical lift. Users can select load cells within the system based on their serial numbers. “You can remotely wake-up load cells that are already rigged in the application, get the signal, and start monitoring to keep equipment, loads, and people safe.”

Insight uises Crosby/Straightpoint’s Proof Test plus software to record data gathered by a Radiolink plus load cell, load shackle or compression load cell, for example. It can create a pass or fail certificate that includes test data and graphs charting data from the load versus time throughout a test.

Another Insight feature is a visual and audible alarm that indicates overload, underload, low battery and communications errors. “The user might want to know when a 1t capacity hoist is at or approaching capacity, and/or a 5t capacity crane is nearing its working load limit. All data can be captured and presented in a report or verified on a certificate, giving users and their customers complete insight and traceability,” added Mullard.

Insight is separate from Crosby/Straightpoint’s Handheld plus device and Bluetooth app. Mullard said that the transition to Insight will typically happen when more than four load cells are being employed and monitored.